The move has come as as it became increasingly clear that it does not make financial sense for the company or the country. But did Holden and its factory workers deserve the public bollocking they’ve received from the Federal Government over the past week?

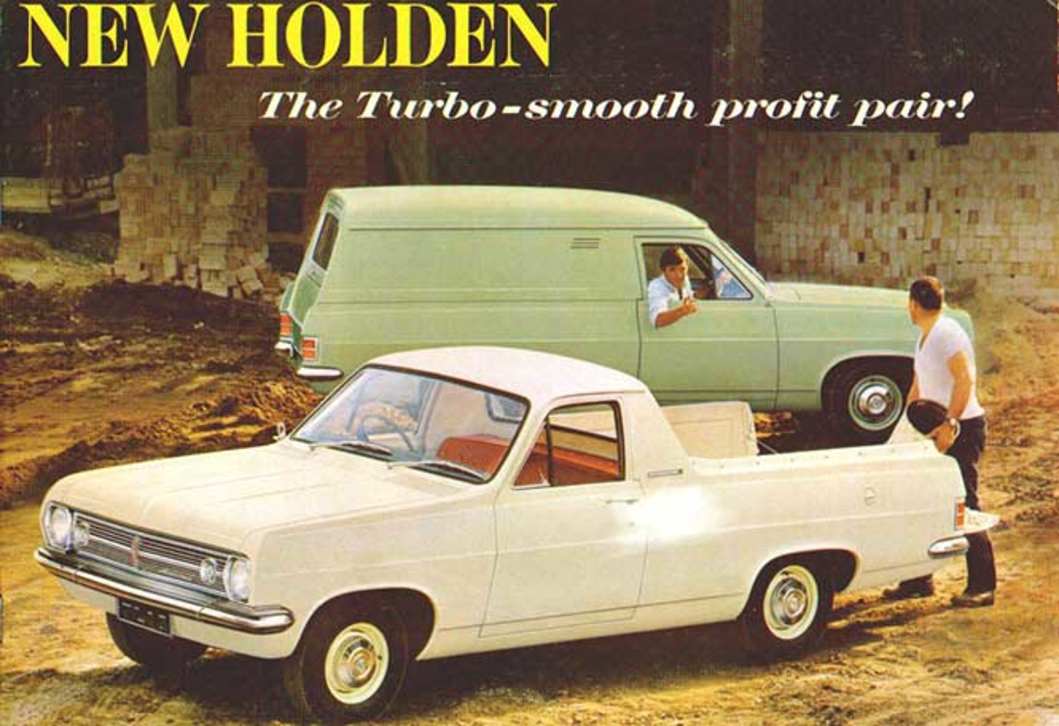

Holden’s crime was to build a factory in what was once the semi-rural outskirts of Adelaide in 1963, that 50 years later would be suffocated by low-cost labour from our Asian neighbours.

At its peak, Holden employed more than 20,000 workers across seven manufacturing facilities. Now there is just one car assembly line and 1760 workers.

Policies from both sides of government over the past half a century have helped shape the economic headwind that Holden drove into: a wealthy nation with a strong currency, high wages and among the lowest import tariffs in the automotive world.

Holden, against this stark backdrop, came to the government for assistance, just as it always has done, in much the same way farmers get a helping hand in times of drought.

The difference, however, is that the future of Australian manufacturing remains bleak because the economic fundamentals are unlikely to change anytime soon.

When Ford announced in May that it would close its Australian factories in 2016, Holden privately wondered why Ford didn’t even give the government the opportunity to help.

It has since emerged that even doubling the government assistance to Ford would not have been enough to save it.

But because Holden feels that its brand image is so closely linked to manufacturing -- even if most of the cars in Holden showrooms today come from South Korea and Thailand -- it decided to raise its hand, Oliver Twist-style, and utter "please, sir, can we have some more?".

Given recent events, however, Holden is probably reconsidering that decision.

The one good call the Federal Government has made in the middle of this Holden sledging campaign is to announce that it will buy bomb-proof BMWs for its politicians instead of hand-built Holdens that can barely withstand a hand-grenade.

Holden was criticised for not pitching for the business. But Holden knows that the likes of Audi, BMW and Mercedes-Benz have specialist divisions that can deliver better equipped armoured cars for less money -- a fitting analogy for the rest of the car industry in fact.

For example, the Cruze is the cheapest locally-made Holden in 20 years. But its sales have been dented by better equipped and cheaper cars from Japan -- buoyed by a currency that has been artificially devalued by the Japanese government.

So where did it all go wrong for Holden?

Holden should have cut its production costs sooner than it did (three months ago it got workers to agree to a three-year wage freeze if the new deal goes ahead).

But Holden cannot be accused of not reacting quickly enough to the changing tastes of Australian car buyers.

It got the Cruze small car into the Elizabeth factory and built it alongside the Commodore in less than two years, in the height of the Global Financial Crisis, when normally such efforts can take up to five years.

No-one wants to take responsibility for Holden's manufacturing shutdown. In the end, Holden was in the wrong place at the wrong time.

Official statement from Holden

As part of its ongoing actions to decisively address the performance of its global operations, General Motors today announced it would transition to a national sales company in Australia and New Zealand. The company also said it would discontinue vehicle and engine manufacturing and significantly reduce its engineering operations in Australia by the end of 2017.

“We are completely dedicated to strengthening our global operations while meeting the needs of our customers,” said GM Chairman and CEO Dan Akerson. “The decision to end manufacturing in Australia reflects the perfect storm of negative influences the automotive industry faces in the country, including the sustained strength of the Australian dollar, high cost of production, small domestic market and arguably the most competitive and fragmented auto market in the world.”

As a result of the company’s actions, approximately 2,900 positions will be impacted over the next four years. This will comprise 1,600 from the Elizabeth vehicle manufacturing plant and approximately 1,300 from Holden’s Victorian workforce.

Holden will continue to have a significant presence in Australia beyond 2017, comprising a national sales company, a national parts distribution centre and a global design studio.

GM Holden Chairman and Managing Director Mike Devereux said an important priority over the next four years would be to ensure the best possible transition for workers in South Australia and Victoria.

“This has been a difficult decision given Holden’s long and proud history of building vehicles in Australia,” said Devereux. “We are dedicated to working with our teams, unions and the local communities, along with the federal and state governments, to support our people.”

The sale and service of Holden vehicles will be unaffected by this announcement and will continue through the extensive network of Holden dealers across Australia and New Zealand. Warranty terms and spare parts availability will remain unchanged.

“GM remains committed to the automotive industry in Australia and New Zealand. We recognize the need for change and understand the government’s point of view. Moving forward, our business model will change significantly however, GM Holden will remain an integral part of its communities and an important employer both directly and through our dealers,” Devereux said.

Since 2001, the Australian dollar has risen from US$0.50 to as high as US$1.10 and from as low as 47 to as high as 79 on the Trade Weighted Index. The Australian automotive industry is heavily trade exposed. The appreciation of the currency alone means that at the Australian dollar’s peak, making things in Australia was 65 percent more expensive compared to just a decade earlier.

With the decision to discontinue vehicle and engine manufacturing in Australia by the end of 2017, GM expects to record pre-tax charges of $400 million to $600 million in the fourth quarter of 2013. The charges would consist of approximately $300 million to $500 million for non-cash asset impairment charges including property, plant and equipment and approximately $100 million for cash payment of exit-related costs including certain employee severance related costs. Additional charges are expected to be incurred through 2017 for incremental future cash payments of employee severance once negotiations of the amount are completed with the employees’ union. The asset impairment charges will be considered special for EBIT-adjusted reporting purposes.

Holden milestones

1948

Prime Minister Ben Chifley unveils the first Holden car, declares “she’s a beauty”. More than 18,000 orders are held before the 48-215 “FX” Holden goes on sale. Some customers sell their place in the queue for £100.

1954

One in three cars on the road is a Holden.

1958

One in two cars on the road is a Holden.

1960

The first export of left-hand-drive Holden vehicles begins with a small shipment of cars to Hawaii.

1962

1 millionth Holden sold (EJ Special sedan, Oct 1962).

1964

Holden employee numbers peak at 23,914 across seven facilities in Queensland, NSW, Victoria and South Australia.

1969

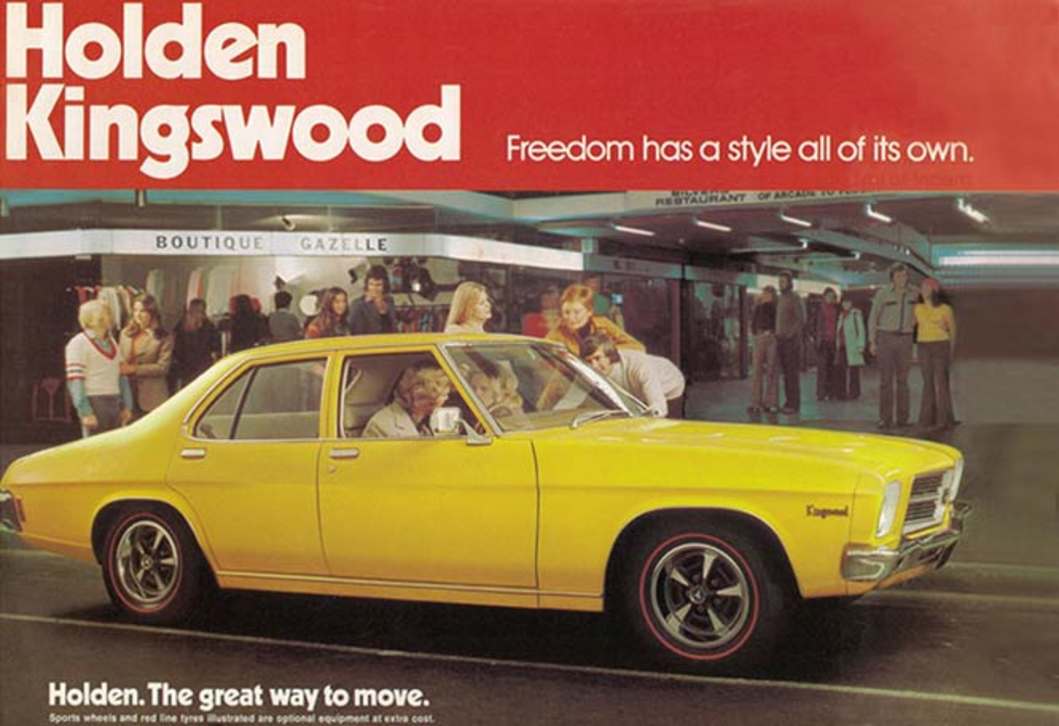

2 millionth Holden sold (HK Kingswood, March 1969).

1974

3 millionth Holden sold (HQ Kingswood, June 1974).

1978

Holden celebrates 25 years of continuous sales leadership.

1981

4 millionth Holden sold (VC Commodore, June 1981).

1990

5 millionth Holden sold (VN Calais, August 1990, more than twice as many as any other Australian built car at the time).

1991

Japanese car-maker Toyota beats Holden and Ford to market leadership for the first time in Australia.

2001

6 millionth Holden sold (VX Commodore SS, June 2001).

2002

The last year Holden led the Australian new-car market.

2004

Holden produces 165,000 vehicles (the most in its modern era), almost matches the 1963 peak of 166,274. Factory worker numbers in 2004: 7350.

2005

Holden’s biggest export year: 60,518 cars were shipped, mostly to the US and the Middle East.

2008

7 millionth Holden sold (VE Commodore LPG, Aug 2008).

2011

After 15 years as Australia’s favourite car, Holden Commodore sales are overtaken by the Mazda3 from Japan. Automotive historians say it is the first time since WWI an imported car has led the new-car market.

2013

Toyota Corolla on track to become Australia’s top-selling car for the first time.

Only five out of 100 new cars sold in Australia is a locally-made Holden.

Holden is overtaken in some months by Mazda, Hyundai and Nissan.

After several redundancies and a three-year wage freeze, Holden factory worker numbers fall to 1760.

Despite a record new-car market, Australian vehicle production falls to its lowest levels since 1958.

Holden is on track to export just 14,000 of the 84,000 cars it will make locally.

-2.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Comments